When it comes to packaging, shipping, or creating custom boxes, understanding length width and height is more than just a basic skill—it’s essential. These dimensions help determine the size of your packaging, shipping costs, and how your product fits inside the box. But many people still wonder: what comes first, and how do you measure them properly?

In this guide by Custom Packaging Pro, we break down the definitions, correct order, measurement tips, and best practices to remove any confusion. Whether you’re a small business owner, a warehouse worker, or just someone mailing a parcel, this article will help you understand the length width and height of boxes the right way.

What Is Length, Width, and Height?

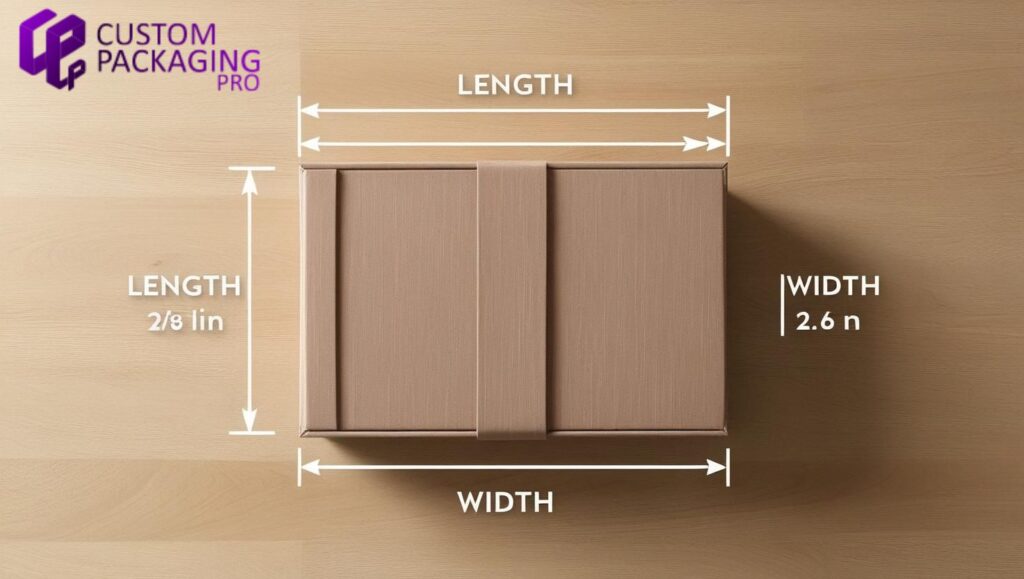

These are the three basic dimensions used to measure a 3D object—usually a box. Let’s define each:

- Length: This is usually the longest side of the object when placed in its typical position. For boxes lying flat, it’s the longest base edge.

- Width: The shorter side of the base, measured from left to right.

- Height (or sometimes called depth): This is the vertical distance from the base to the top of the object.

💡 Tip: If you place a box on a table, the part facing the ceiling is the height, the front edge is the length, and the side edge is the width.

Why Does the Order Matter?

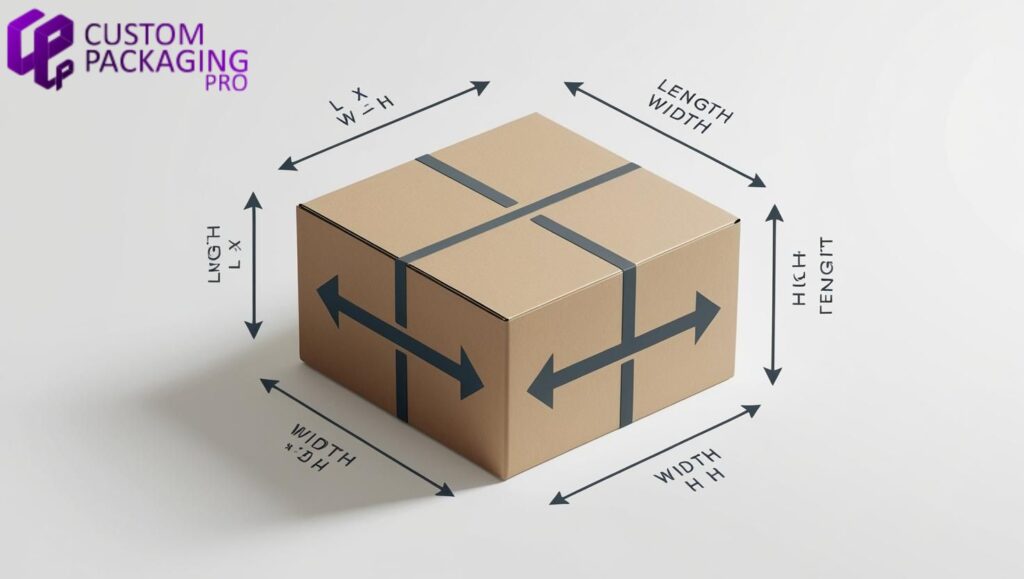

You may have seen dimensions written in several ways: Length x Width x Height, or sometimes Height x Width x Length. While the first is the standard and most commonly accepted format, different industries may switch the order based on context or orientation.

But here’s a general rule of thumb:

📦 Standard Order:

Length x Width x Height (L x W x H)

Use this format unless specified otherwise. It’s the most widely accepted and helps avoid confusion during shipping or custom box manufacturing.

Measuring Length Width and Height of a Box

To measure any box or package correctly, follow these simple steps:

- Place the Box Flat: Put it on a level surface.

- Length: Measure the longest side of the base.

- Width: Measure the shorter side of the base (left to right).

- Height: Measure from the base to the top of the box (vertical side).

Use a measuring tape or ruler and always measure in inches or centimeters, depending on your standard. This ensures consistent results across the packaging and shipping process.

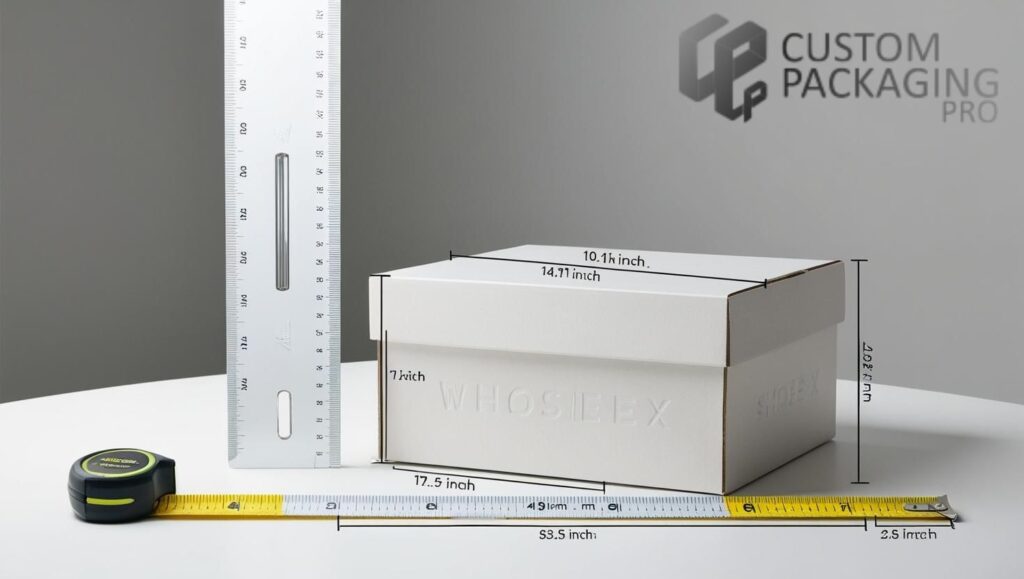

Real-Life Examples of Length Width and Height

Let’s say you have a shoebox with the following measurements:

- Length: 13 inches

- Width: 9 inches

- Height: 5 inches

This would be listed as 13” x 9” x 5” (L x W x H) on most packaging labels. These values not only tell you the size but also help in calculating shipping volume, storage space, and design layout for labels or logos.

Why Are These Dimensions Important in Packaging?

- Accurate Shipping Charges: Most carriers use dimensional weight to calculate shipping costs. Bigger boxes—even if lightweight—can cost more.

- Proper Fit for Products: Getting the size wrong can lead to damage, waste, or unprofessional presentation.

- Design Placement: If you’re creating custom boxes with a logo, knowing the exact layout helps place branding and information correctly.

At Custom Packaging Pro, we help clients ensure the correct box sizes and dimensions are used, whether it’s for food packaging, retail boxes, or e-commerce shipping.

The Difference Between Height and Depth

In many cases, height and depth are used interchangeably, but there’s a subtle difference depending on the industry:

- Height usually refers to the vertical measurement of a standing object.

- Depth is often used when referring to how far back something goes—like the inside of a drawer.

💬 Voice Search Tip:

If someone asks, “What’s the depth of this box?”, they likely mean the vertical height, depending on how the box is positioned.

How to Calculate Volume with Length, Width, and Height

One major use of these measurements is to calculate volume:

📐 Formula:

Volume = Length × Width × Height

Example:

A box that measures 10” x 8” x 6” would have:

Volume = 10 × 8 × 6 = 480 cubic inches

Volume is important when:

- Estimating how much product fits inside

- Planning storage

- Calculating shipping cost based on dimensional weight

Common Dimension Orders and When to Use Them

| Format | Use Case |

|---|---|

| Length x Width x Height | Standard format for packaging and shipping |

| Height x Width x Length | When the box stands vertically (e.g., bottles) |

| Width x Height x Depth | Often used in furniture or cabinetry |

Consistency is key. As long as you’re clear and stick to one format, you’ll avoid confusion in communication and logistics.

Best Practices for Measuring Boxes

✅ Use a rigid tape measure

✅ Measure from the outside edges

✅ Round to the nearest 0.1 inch or centimeter

✅ Double-check all three values

✅ Communicate the order (L x W x H) clearly in specifications

Whether you’re printing it on the box or entering it into a shipping form, a tiny mistake in dimension order can cause major delays or costs.

FAQs About Length Width and Height

Q1. What is the correct order of dimensions: length width and height?

A: The standard order is Length x Width x Height.

Q2. Can I use height instead of depth?

A: Yes, in most packaging cases, height and depth mean the same thing, but clarify if needed.

Q3. How do I calculate box volume using dimensions?

A: Multiply the length, width, and height (L × W × H).

Q4. Why does dimension order matter in packaging?

A: It ensures accurate box sizes, fitting, and shipping calculations.

Q5. Is width the same as breadth?

A: Yes, in many contexts, breadth and width are used interchangeably.

Final Thoughts

Understanding length width and height is more than just knowing numbers. It’s about precision, clarity, and efficiency—especially when packaging matters. Whether you’re designing boxes, printing labels, or shipping products, mastering these three dimensions gives you full control over your packaging game.

Need help with custom sizing or printed boxes? Custom Packaging Pro is here to guide you with expert support, quality materials, and exact dimensions—every single time.