When it comes to welding projects that demand superior corrosion resistance, strength, and durability, Monel welding wire often emerges as the material of choice. Whether you’re working on marine equipment, chemical processing plants, or high-temperature environments, selecting the right Monel welding wire can make a significant difference in the quality and longevity of your welds.

In this comprehensive guide, we will explore everything you need to know about Monel welding wire—from its properties and types to practical tips for choosing the perfect wire for your specific project needs.

What is Monel Welding Wire?

At its core, Monel Welding Wire is a filler material made primarily of nickel and copper, designed specifically for welding Monel alloys and other similar nickel-copper alloys. Monel itself is a trademarked name for a group of nickel alloys known for their excellent corrosion resistance and toughness.

The welding wire is used in various processes such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and even submerged arc welding, depending on the specific type of Monel wire and project requirements.

Key Characteristics of Monel Welding Wire

- Corrosion resistance: Monel welding wire excels in harsh environments, resisting corrosion caused by seawater, acids, and alkalis.

- High strength: It provides mechanical strength in extreme conditions, maintaining integrity under stress.

- Good ductility: It offers flexibility in welding applications, reducing cracking risks.

- Heat resistance: Can withstand elevated temperatures without losing performance.

Why Choose Monel Welding Wire?

Understanding why Monel welding wire is preferred in certain industries will help you appreciate its value for your project.

Superior Corrosion Resistance

One of the most significant advantages of Monel welding wire is its outstanding resistance to corrosion, especially in marine and chemical environments. If your project involves exposure to saltwater or aggressive chemicals, Monel welding wire ensures longevity by preventing rust and degradation.

Versatility in Applications

From piping systems and heat exchangers to aerospace components, Monel welding wire is versatile. It’s suitable for welding Monel alloys, Inconel, and other nickel-based alloys, making it a go-to filler material in industries where reliability is non-negotiable.

High-Temperature Performance

Projects involving elevated temperatures require materials that won’t degrade or lose strength. Monel welding wire maintains performance even in high-heat settings, making it ideal for components in power plants and engines.

Different Types of Monel Welding Wire

Choosing the right Monel welding wire starts with knowing the types available in the market.

Monel 400 Welding Wire

The most common Monel welding wire is the Monel 400 welding wire, composed of approximately 67% nickel and 23% copper. It’s a versatile wire used for general-purpose welding, especially in chemical and marine applications.

Key benefits:

- Excellent corrosion resistance

- Good mechanical strength

- Suitable for joining Monel 400 alloy and similar materials

Monel K-500 Welding Wire

Monel K-500 wire contains additional elements like aluminum and titanium, which enhance its strength and hardness. This wire is preferred when higher strength is needed alongside corrosion resistance.

Ideal for:

- Aerospace and marine hardware

- Applications requiring higher tensile strength

Other Nickel-Copper Alloy Wires

Depending on project requirements, you might also find other nickel-copper alloy welding wires designed for specific purposes, such as welding copper-nickel alloys or specialty nickel alloys.

Factors to Consider When Choosing Monel Welding Wire

Selecting the right wire involves more than just picking the right type. Here are essential factors to weigh before making your choice.

1. Base Metal Compatibility

Always match the welding wire to the base metal you intend to join. For example, use Monel 400 welding wire for Monel 400 alloy base metals. This ensures a strong, corrosion-resistant weld.

2. Welding Process

Different welding processes require different wire types and diameters. TIG welding generally uses thinner wire for precision, while MIG welding can utilize thicker wire for faster deposition.

- TIG welding: Preferred for thin sections and precise control.

- MIG welding: Better for thicker materials and faster work.

- Stick welding: Less common for Monel but used in some industrial applications.

3. Wire Diameter

The thickness of the wire affects welding speed and penetration. Common diameters range from 0.030 inches (0.8 mm) to 0.045 inches (1.2 mm), but your choice depends on material thickness and welding process.

4. Mechanical Properties Required

Consider tensile strength, hardness, and ductility needed for the finished weld. Monel K-500 wire, for example, offers higher strength but less ductility compared to Monel 400.

5. Environmental Conditions

Exposure to chemicals, seawater, or extreme temperatures influences your choice. Monel wires excel in such environments but be sure to specify which grade suits your needs best.

How to Properly Store and Handle Monel Welding Wire

Maintaining the quality of Monel welding wire before and during welding is critical for optimal results.

- Store in a dry, clean environment to prevent contamination.

- Avoid exposure to moisture, which can cause oxidation and weld defects.

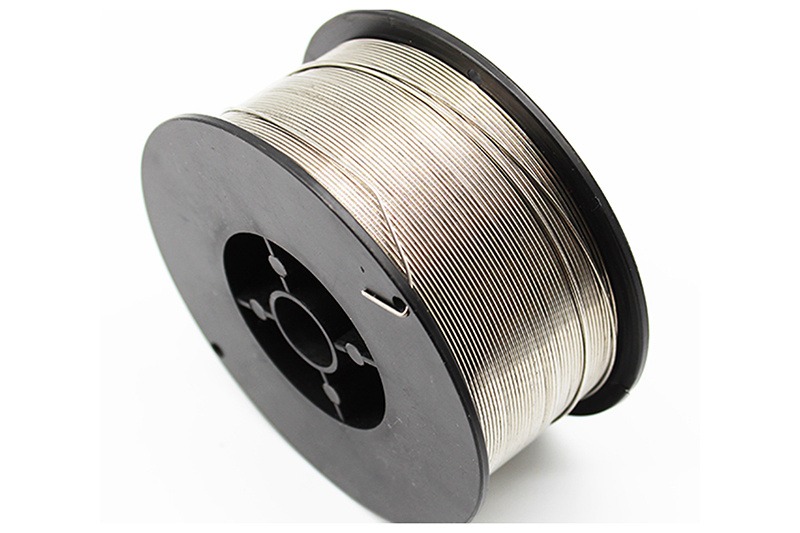

- Use wire spools compatible with your welding machine to prevent tangling or feeding issues.

- Handle wires carefully to prevent kinks or bends that might weaken the weld.

Common Applications of Monel Welding Wire

Understanding the typical uses of Monel welding wire helps clarify why it’s a popular choice in many industries.

Marine and Offshore Industry

Monel’s resistance to seawater corrosion makes the welding wire ideal for shipbuilding, offshore platforms, and underwater pipelines.

Chemical Processing Plants

The wire’s ability to withstand acidic and alkaline environments allows for reliable welding in chemical reactors and storage tanks.

Aerospace and Aviation

High strength and corrosion resistance make Monel welding wire suitable for aircraft components exposed to harsh conditions.

Power Generation

In turbines, heat exchangers, and nuclear reactors, Monel welding wire helps maintain integrity under high temperatures and pressures.

Conclusion

Choosing the right Monel welding wire is a vital decision that influences the strength, durability, and lifespan of your welded structures. By understanding the types of Monel wire, considering your project’s environmental and mechanical requirements, and following best welding practices, you can ensure a successful outcome.

Remember, quality begins with the right materials. Investing time in selecting the correct Monel welding wire pays dividends in the reliability and safety of your finished work.