In today’s fast-paced industrial landscape, warehouses must operate with maximum efficiency to meet tight deadlines, reduce costs, and improve customer satisfaction. One often overlooked tool that plays a crucial role in streamlining operations is the pallet scale. Positioned strategically at loading docks, pallet scales significantly enhance workflow by ensuring accurate weight measurement, improving load management, and supporting compliance with safety and shipping regulations.

What Are Pallet Scales?

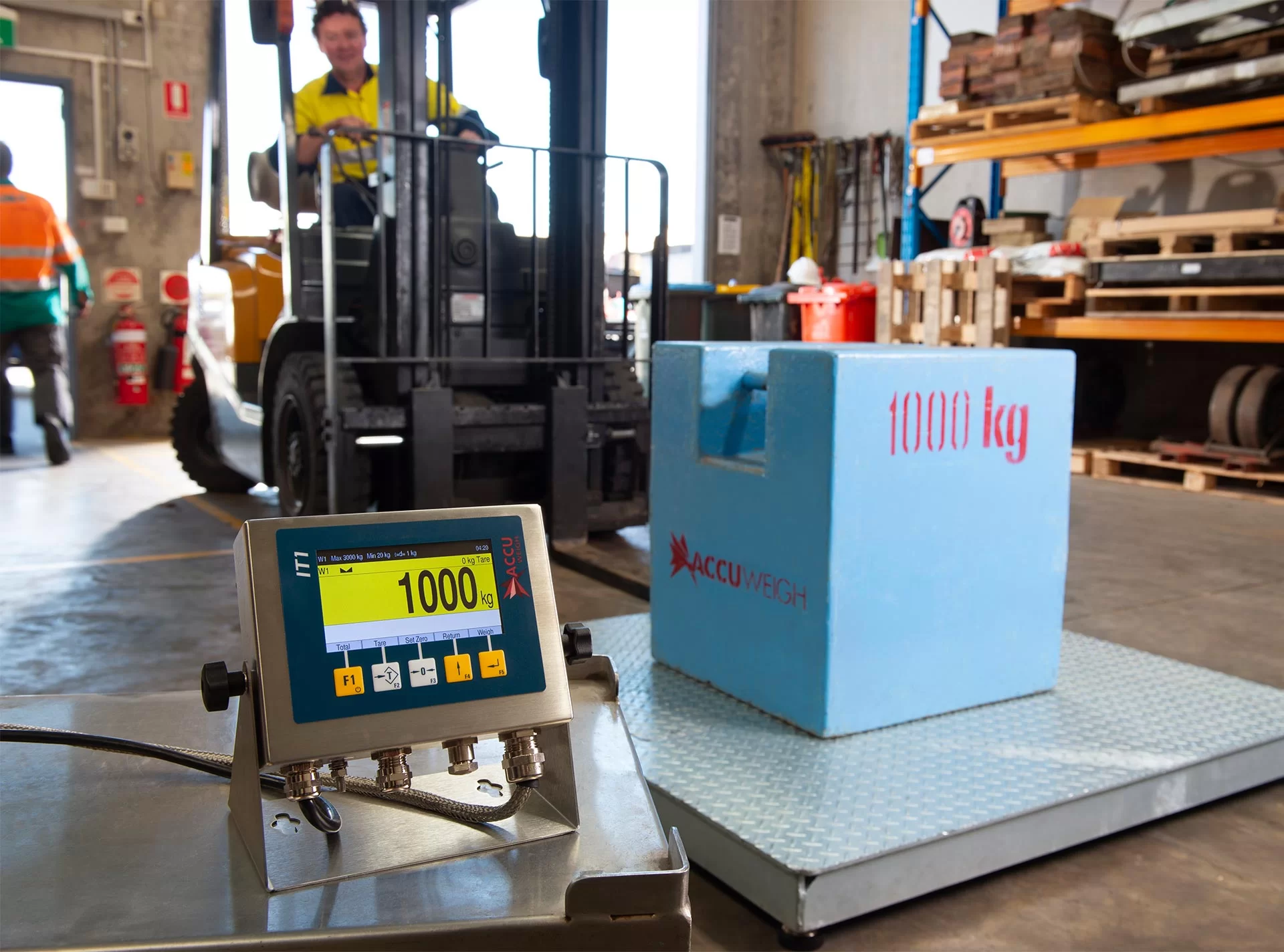

Pallet scales are industrial-grade weighing devices specifically designed to weigh pallets of goods. These scales come in various forms, including floor-mounted platforms, pallet jack scales, and forklift-integrated versions. They are built to handle heavy loads and rugged warehouse conditions, providing accurate weight data for inbound and outbound shipments.

Key Benefits of Using Pallet Scales at Loading Docks

1. Improved Efficiency in Shipping and Receiving

At the loading dock, time is of the essence. Pallet scales allow warehouse staff to weigh goods quickly as they are being loaded or unloaded, reducing the need to move items to separate weighing stations. This immediate weight verification speeds up the entire shipping and receiving process, reducing bottlenecks and labor hours.

2. Accurate Load Management

Using pallet scales helps ensure that trucks are loaded correctly and within legal weight limits. Overloaded trucks can incur fines, cause delivery delays, or pose safety risks. Accurate weight data from pallet scales helps logistics teams distribute weight evenly and plan optimal truckloads, ensuring safer and more efficient transportation.

3. Real-Time Inventory Updates

Integrating pallet scales with warehouse management systems (WMS) allows for real-time inventory updates. As pallets are weighed and scanned, their data is automatically entered into the system, reducing manual entry errors and improving stock accuracy. This leads to better inventory control and easier demand forecasting.

4. Enhanced Workplace Safety

Accurate weight measurements reduce the risk of accidents caused by overloading equipment such as forklifts or conveyors. Pallet scales contribute to a safer work environment by helping staff adhere to safe load-handling practices and minimizing the risk of injuries.

5. Regulatory Compliance

Many industries, including food, pharmaceuticals, and logistics, must comply with strict shipping and packaging weight regulations. Pallet scales provide the precision necessary to meet these compliance standards, helping businesses avoid costly penalties and maintain quality assurance.

Choosing the Right Pallet Scale for Your Loading Dock

When selecting a pallet scale, it’s essential to consider your specific warehouse needs. Here are some factors to guide your decision:

- Capacity and Accuracy: Choose a scale that matches the weight and size of your typical pallet loads.

- Durability: Look for scales made from industrial-grade materials, such as stainless steel or powder-coated steel, to withstand harsh warehouse conditions.

- Mobility: For flexibility, consider pallet jack scales or mobile platform scales that can be easily moved to different areas of the dock.

- Integration Capabilities: Ensure the scale can connect with your WMS or ERP systems for seamless data management.

- Ease of Use: Opt for models with intuitive digital displays and user-friendly interfaces to minimize training time.

Integrating Pallet Scales into Your Workflow

Proper implementation of pallet scales at loading docks requires thoughtful planning and staff training. Here are a few best practices:

- Position Strategically: Place scales at key entry and exit points where pallets are most frequently loaded and unloaded.

- Train Employees: Ensure that all staff members understand how to operate the scales correctly and interpret the data.

- Routine Maintenance: Regular calibration and inspection ensure accuracy and longevity of the equipment.

- Data Management: Use the weight data collected to generate reports, analyze trends, and improve decision-making.

Case Study: Pallet Scales in Action

A large distribution center implemented pallet scales at all their loading dock stations. Before integration, manual weighing procedures slowed down operations and often led to discrepancies in shipping documents. Post-integration, the center reported a 30% increase in loading speed and a 15% reduction in shipping errors. Real-time data allowed the team to optimize truck loading and enhance customer satisfaction through accurate and timely deliveries.

Conclusion

Incorporating pallet scales into loading dock operations is a cost-effective and efficient way to improve warehouse workflow. From enhancing shipping accuracy to promoting safety and compliance, these scales serve as a critical component in modern logistics. As supply chains grow increasingly complex, investing in reliable pallet scales is a smart move for any warehouse aiming to stay competitive and deliver excellence.

Whether you’re upgrading your current system or designing a new facility, consider pallet scales not just as a tool, but as a strategic asset that drives productivity, accuracy, and customer trust.