When it comes to fluid control in high-pressure, high-temperature, or abrasive environments, metal seated sluice valves are the gold standard. These industrial valves are essential across sectors like water treatment, oil and gas, mining, and manufacturing. In India, the demand for long-lasting and high-performance valves continues to grow—and at resilientgatevalve, we’ve built our reputation by meeting that demand with excellence.

In this article, we break down why metal seated sluice valves remain unmatched in strength and performance, how they are designed to endure extreme conditions, and why choosing the right Metal Seated Sluice Valve Manufacturer matters more than ever.

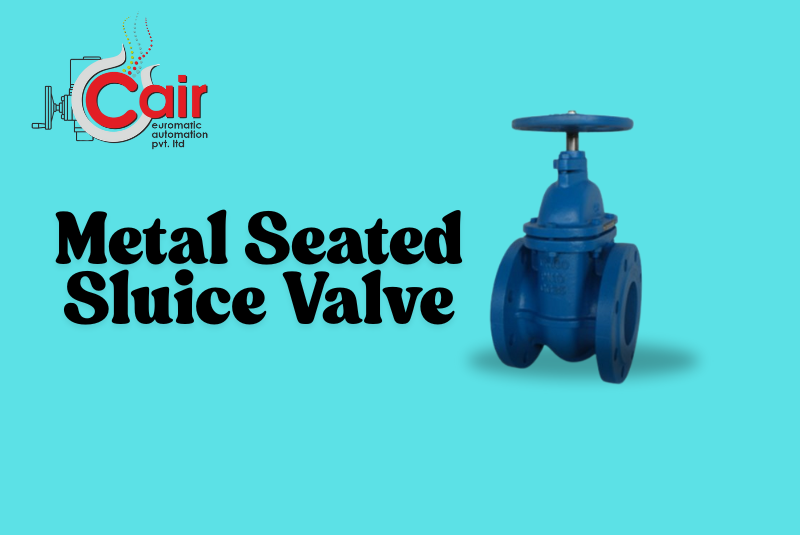

What is a Metal Seated Sluice Valve?

A metal seated sluice valve is a gate valve used to control the flow of liquids by raising or lowering a solid gate into the path of the fluid. Unlike resilient seated valves (which use rubber or elastomeric seals), metal seated valves use metal-to-metal contact, making them ideal for tough environments where sealing materials might degrade.

Their rugged design makes them ideal for:

- High-pressure operations

- Abrasive or corrosive fluids

- High-temperature pipelines

Core Advantages of Metal Seated Sluice Valves

1. Unmatched Strength

The metal-to-metal sealing provides exceptional resistance to wear and tear. These valves are engineered to withstand extreme mechanical stresses, making them reliable in the harshest conditions. Whether it’s thermal cycling or high-velocity flow, they maintain performance where others fail.

2. Superior Durability

Metal seated valves have a longer operational life, especially when exposed to aggressive fluids or slurries. Industries such as steel plants, thermal power stations, and chemical processing units often prefer these valves for their extended lifecycle and minimal maintenance requirements.

3. High-Temperature Resistance

Elastomeric seals may deform or melt under high heat, but metal seated sluice valves thrive under such conditions. Their structure ensures reliable operation even in steam lines and high-temperature processes.

4. Corrosion and Abrasion Resistance

Our valves at resilientgatevalve are manufactured using corrosion-resistant alloys, ensuring optimal performance even in acidic or abrasive environments. This makes them suitable for industrial wastewater management and seawater applications.

Common Industrial Applications in India

From municipal water supply to mining, metal seated sluice valves serve a broad range of applications:

- Power Plants: For managing high-temperature and high-pressure steam.

- Irrigation and Water Supply Schemes: Especially where long-term durability is essential.

- Sewage and Drainage Systems: Their rugged design ensures resistance to suspended solids.

- Industrial Slurry Pipelines: Common in cement and mining industries.

- Refineries and Chemical Plants: Where fluid properties vary and demand robust sealing.

As a leading Resilient Seated Sluice Valve Manufacturer in India, we also produce Metal Seated Sluice Valves that cater to these high-demand applications.

Comparison: Metal vs. Resilient Seated Sluice Valves

| Feature | Metal Seated Sluice Valve | Resilient Seated Sluice Valve |

|---|---|---|

| Seal Type | Metal-to-metal | Rubber/elastomer-based |

| Temperature Tolerance | High | Moderate |

| Abrasion Resistance | High | Moderate |

| Maintenance | Low | May require more frequent checks |

| Ideal Use Case | Industrial, heavy-duty | Municipal, light-duty |

While resilient seated valves are suitable for general water distribution, metal seated valves are indispensable where environmental conditions are severe. At resilientgatevalve, we offer both, understanding the unique demands of each application.

Integrating with Other Valve Solutions

Air Valves Single and Double

When managing long water pipelines, incorporating Air Valves Single and Double alongside sluice valves ensures pressure surges are minimized. These valves release trapped air and protect the pipeline system from collapse or water hammer effects.

Non Return Valve

To prevent backflow and maintain unidirectional flow, Non Return Valves work in tandem with sluice valves in water and sewage systems. They add another layer of operational efficiency and system safety.

Pressure Reducing Valve

In multi-zonal supply networks, Pressure Reducing Valves are crucial for maintaining consistent output pressure. They protect downstream components, including metal seated sluice valves, from excessive pressure build-up.

Our full range of industrial valve solutions at resilientgatevalve ensures that clients receive an integrated, long-lasting, and high-performance system tailored to their exact needs.

Why Choose resilientgatevalve?

As a trusted Metal Seated Sluice Valve Manufacturer in India, we pride ourselves on:

- Precision Engineering: Every valve is designed with exacting standards to meet Indian and international specifications.

- IS 14846 Compliance: Our metal seated sluice valves conform to IS 14846 standards, ensuring quality, reliability, and compatibility.

- Customized Solutions: We understand that each industry faces unique challenges, and we offer tailored valve designs based on your requirements.

- After-Sales Support: Our support doesn’t end at delivery. We offer technical guidance, installation support, and spare parts availability.

When you partner with resilientgatevalve, you’re not just buying a product—you’re investing in long-term performance and peace of mind.

Sustainability & Quality Control

Environmental responsibility is at the core of our manufacturing philosophy. Our plant operations focus on:

- Reducing energy consumption

- Minimizing waste

- Using recyclable materials

Each metal seated sluice valve undergoes rigorous quality checks for leakage, pressure resistance, and mechanical durability before dispatch. This ensures that every unit you receive meets the highest performance standards.

Conclusion

Metal seated sluice valves are the backbone of industrial fluid control in India. Their ability to operate reliably under harsh conditions—be it temperature, pressure, or abrasion—makes them the preferred choice across various sectors. When paired with supporting valves like Air Valves Single and Double, Non Return Valve, and Pressure Reducing Valve, they form a cohesive, efficient, and reliable pipeline system.

At resilientgatevalve, we bring decades of expertise and innovation to every product we manufacture. As a premier Resilient Seated Sluice Valve Manufacturer, we understand the nuances of your operational challenges and deliver valves engineered to exceed expectations.