Choosing an appropriate power drill is crucial to ensuring your project turns out well. From simple home repairs to professional construction tasks, understanding the features and best practices for each type of drill will save you time, effort, and frustration. In this guide, we explore the most common power drills, explain their ideal applications, and share tips on how to use each one efficiently – baut – tokohasil.

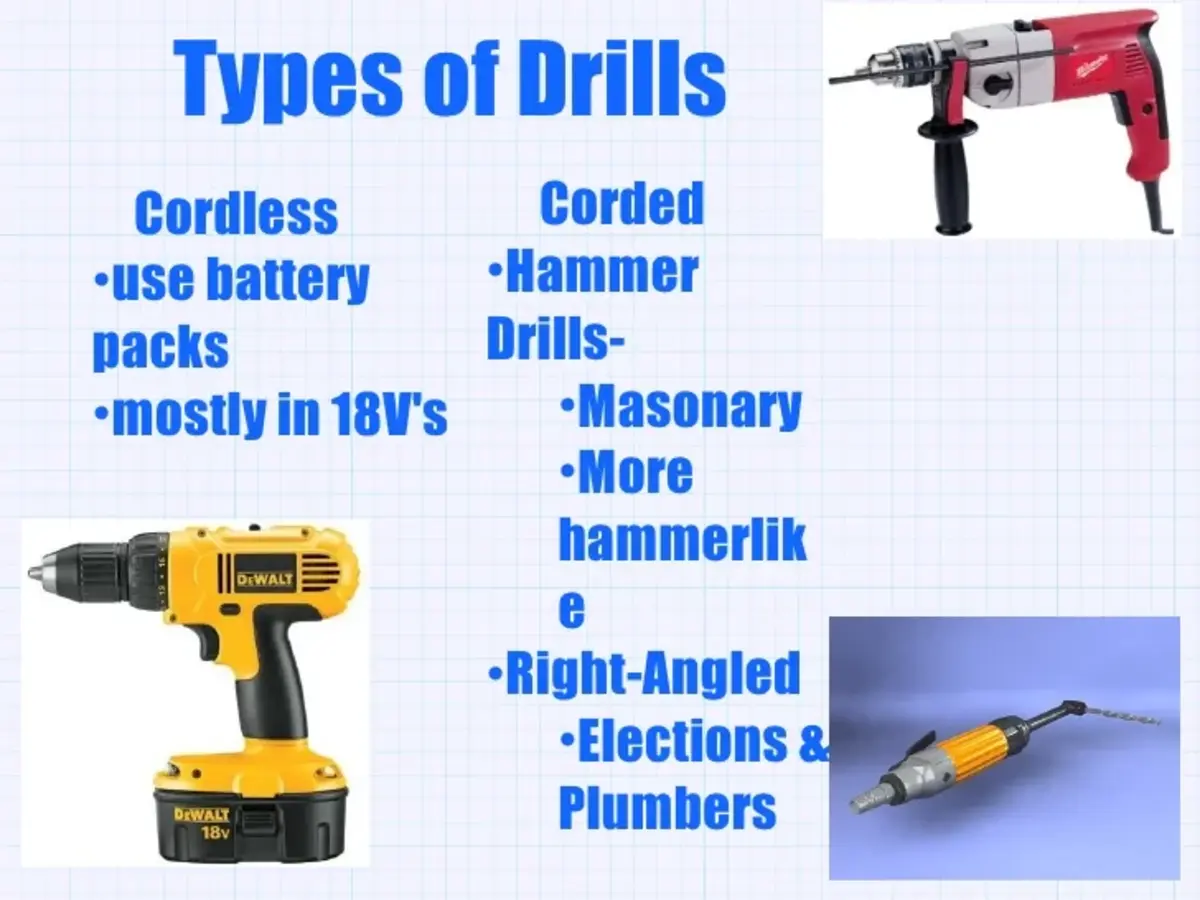

Cordless Drill

Cordless drills are the most versatile and popular among DIY enthusiasts and professionals alike. Powered by rechargeable batteries, they offer freedom of movement without the hassle of a power cord.

Key Features: Variable speed control, adjustable clutch settings, keyless chuck

Best Uses: Drilling holes in wood, metal, plastic, and driving screws in furniture assembly

Efficiency Tips:

- Keep extra batteries charged and ready.

- Align the drill bit dimensions with the screw size or the diameter of the hole you need.

- Use the clutch to prevent stripping screw heads.

Corded Drill

Corded drills deliver consistent power and torque, making them ideal for heavy-duty tasks. They require an electrical outlet, but their continuous power output allows for longer operation without battery swaps.

Key Features: Higher torque levels, variable speed triggers, three-jaw keyed chuck

Best Uses: Drilling deep holes in masonry and metal, mixing paint or mortar with a paddle attachment

Efficiency Tips:

- Secure the cord away from the drilling area to avoid accidents.

- Choose the correct drill bit for the material—masonry bits for concrete, high-speed steel bits for metal.

- Use a side handle for better control during tough drilling jobs.

Hammer Drill

Hammer drills use both spinning motion and rapid hammering to break through tough surfaces while drilling.

. This makes them indispensable for masonry work.

Key Features: Dual-mode switch (drill vs. hammer), adjustable hammering force, robust motor

Best Uses: Drilling into brick, concrete, stone, and block

Efficiency Tips:

Start drilling at low speed to create a precise pilot hole.

Apply steady pressure; let the tool’s hammer mechanism do the work.

Put on protective eyewear and hearing gear to guard against loud sounds and airborne particles.

Impact Driver

Impact drivers offer bursts of high torque that make driving long screws and fasteners effortless. They work differently than drills, using rotational impacts to drive screws without cam-out.

Key Features: Quick-change hex chuck, compact design, variable speed trigger

Best Uses: Driving deck screws, lag bolts, and other heavy fasteners in wood and metal

Efficiency Tips:

Pair with impact-rated driver bits to avoid bit breakage.

Apply brief, controlled pulses to manage how deep the screw goes.

Keep a magnetic bit holder for quick bit swaps.

Drill Press

A drill press is a fixed tool mounted on a workbench, designed to produce accurate, vertical holes. Ideal for workshops, it excels when accuracy and repeatable hole placement matter.

Key Features: Adjustable table height, depth stop, belt-driven speed settings – Best Uses: Precision drilling in wood, metal, and plastic for furniture making, jigs, and templates

Efficiency Tips:

Clamp workpieces securely to prevent movement.

Change the belt setting to suit the type of material and the size of the drill bit.

Lubricate metal bits and surfaces to reduce friction and heat.

Right-Angle Drill

Right-angle drills feature a compact head that allows access to tight or confined spaces. Their form factor is perfect for plumbing, electrical, and cabinetry work where clearance is limited.

Key Features: 90-degree head, variable speed, built-in LED light

Best Uses: Drilling in corner studs, between joists, and inside cabinets

Efficiency Tips:

Use short, stubby bits designed for right-angle drills.

Switch to drill mode for holes, clutch mode for driving screws.

Keep hands clear of cramped areas to prevent injury.

Rotary Hammer

Rotary hammers are heavy-duty tools that use a piston mechanism for a powerful hammering action. They outclass hammer drills for large concrete demolition and deep masonry holes.

Key Features: SDS-plus or SDS-max bit system, selectable modes (hammer only, drill only, hammer drill)

Best Uses: Chiseling concrete, drilling large-diameter holes for anchors and rebar

Efficiency Tips:

Wear vibration-reducing gloves to lessen hand fatigue.

Use the correct SDS bit size to match anchor or dowel requirements.

Maintain a firm grip and use auxiliary handles for stability.

Choosing the right drill starts with understanding your project’s requirements. Cordless and corded drills cover general tasks, while hammer drills and rotary hammers tackle masonry. Impact drivers and right-angle drills specialize in fastening and tight spaces, and drill presses ensure pinpoint accuracy. By matching each power drill to its optimal use and following these efficiency tips, you’ll complete tasks faster, maintain better tool control, and achieve professional-quality results. Whether building a deck, installing cabinets, or setting anchors in concrete, the right power drill empowers you to work smarter, not harder.