Pre-Engineered Buildings (PEBs) have revolutionized modern construction with their cost-effectiveness, speed of construction, and adaptability to different industrial and commercial applications. One of the most important aspects of PEB design is the roofing system. Selecting the right roof type not only affects the building’s structural integrity but also impacts ventilation, insulation, and aesthetic appeal. This article explores the different Types Of Roof In PEB Construction, helping builders, architects, and project owners make informed decisions.

1. Gable Roof

The gable roof is the most commonly used among the types of roof in PEB construction. It features two sloping sides that meet at a central ridge, forming a triangular cross-section. This type of roof offers excellent water drainage, especially in regions with heavy rainfall or snowfall. Gable roofs are easy to design and construct, making them cost-effective and structurally reliable. Additionally, they provide ample attic space and ventilation.

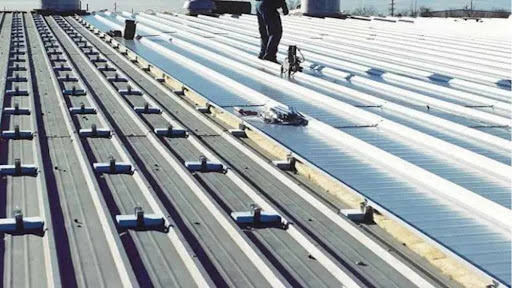

2. Single Slope Roof

Another popular choice among the types of roof in PEB construction is the single slope or mono-slope roof. As the name suggests, it has only one sloping surface, slanting from one side to the other. This design is ideal for buildings where water runoff needs to be directed to one specific side. Single slope roofs are particularly useful in warehousing and manufacturing units.

3. Curved Roof

Curved roofs are aesthetically modern and are gaining popularity in architectural designs of PEBs. This type of roof features a smooth, curved surface instead of angular ridges. Among the various types of roof in PEB construction, curved roofs stand out for their design flexibility and modern look. They are often used in sports complexes, exhibition halls, and airports.

4. Multi-Gable Roof

Multi-gable roofs combine multiple gable roof sections, typically seen in more complex or larger PEB structures. This type is common in industrial buildings that require various sections or divisions within the same structure. Among the types of roof in PEB construction, multi-gable roofs offer high customization and structural balance.

5. Arch Roof

Arch roofs are a sophisticated variant often used in large-span PEB structures like aircraft hangars and warehouses. They provide strength and stability due to their curved profile. These roofs are efficient in distributing loads and resisting environmental pressures, making them a significant type among the types of roof in PEB construction

6. Saw-Tooth Roof

The saw-tooth roof is characterized by a series of ridges with dual pitches on either side, one being steeper than the other. It resembles the teeth of a saw when viewed from the side. This design allows natural light to enter through the vertical sides, which are usually glazed. Among the energy-efficient types of roof in PEB construction, the saw-tooth roof is ideal for factories and manufacturing units.

7. Lean-to Roof

The lean-to roof is one of the simpler types of roof in PEB construction, often used as an extension of an existing building. It has a single slope and is supported at one end by a higher wall. This design is cost-effective and ideal for smaller structures or for expanding existing facilities.

8. Pyramid Roof

Pyramid roofs, or hipped roofs with equal sides, are used in specialized architectural designs. Although not very common in industrial PEBs, they are used in commercial or institutional buildings for their aesthetic appeal. As one of the more unique types of roof in PEB construction, pyramid roofs offer excellent wind and rain resistance

Conclusion

Choosing the right roofing type is critical to the success and efficiency of any pre-engineered building. The types of roof in PEB construction discussed above serve a variety of functional and aesthetic needs. Whether it’s the practical single slope, the classic gable, or the visually distinct curved roof, each option brings its unique set of advantages.

With the growing adoption of PEBs across industries, understanding the types of roof in PEB construction becomes increasingly important. The correct choice can enhance energy efficiency, reduce maintenance costs, and extend the life of the building. By assessing project requirements, environmental conditions, and budget considerations, stakeholders can select the most appropriate roof type for their PEB structure.

In summary, the key to a successful PEB lies in choosing the right components—and the types of roof in PEB construction play a pivotal role in that decision-making process.