The maritime industry is a cornerstone of global trade, with ships transporting over 80% of world merchandise by volume. Behind this massive movement lies an intricate network of mechanical systems that power, sustain, and operate vessels efficiently. Ship machineries are vital not only for propulsion and navigation but also for ensuring crew safety, environmental compliance, and cargo security. This article explores the critical types of ship machineries, the role of advanced materials like stainless steel 904L in marine engineering, and why choosing the right suppliers can make all the difference.

Key Ship Machineries and Their Functions

1. Main Propulsion Systems

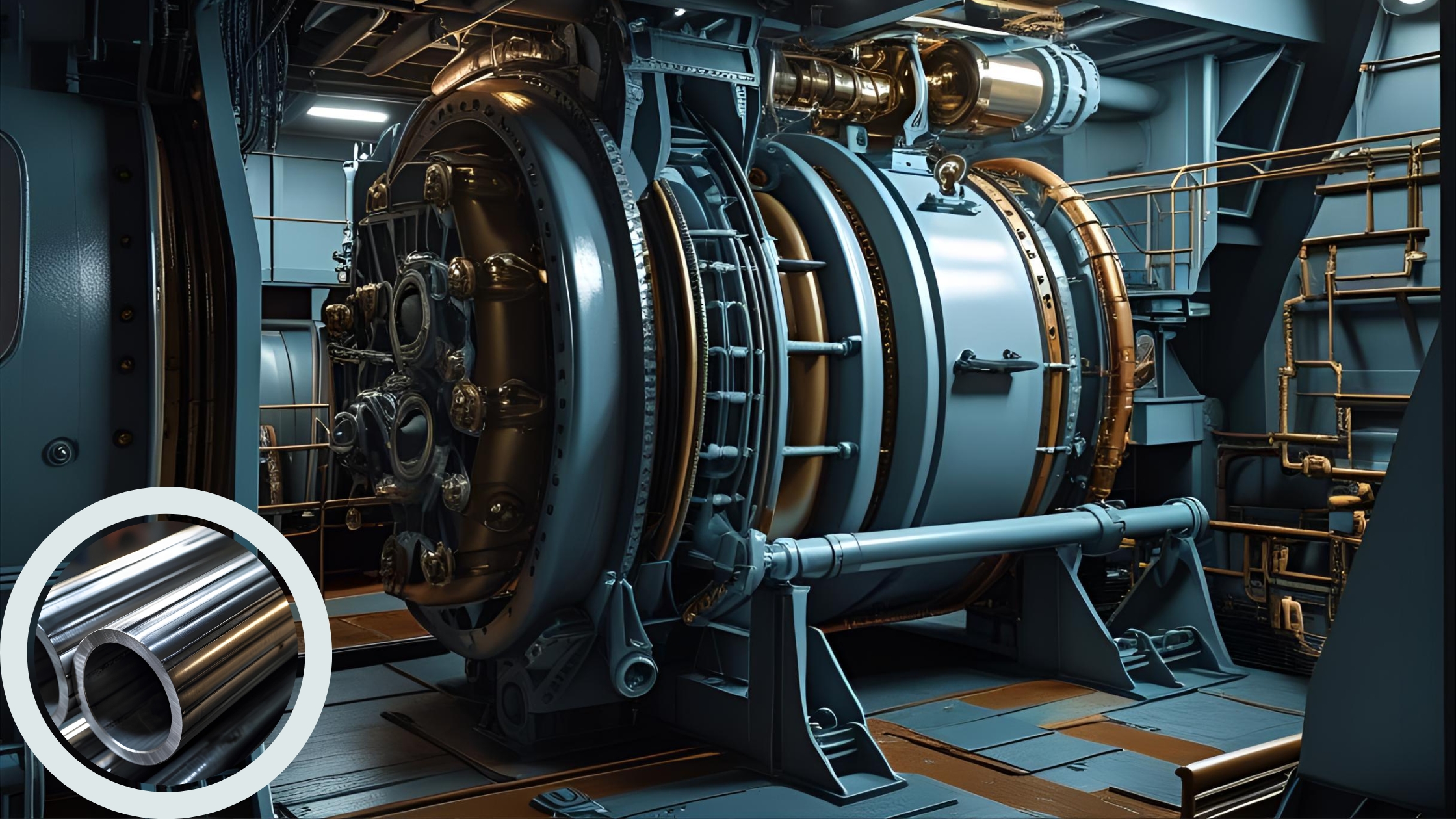

The main propulsion system is the heart of any vessel. It typically comprises a large marine diesel engine, transmission components such as reduction gearboxes, and a propulsion mechanism like a fixed or controllable pitch propeller. The main engine is designed to deliver maximum power and efficiency for long-distance travel, with minimal fuel consumption and emissions.

Modern propulsion systems may also include hybrid setups, integrating electric drives with traditional engines for enhanced fuel efficiency and environmental sustainability. These systems operate under harsh marine conditions and require components that can withstand high temperatures, vibrations, and exposure to saltwater.

2. Auxiliary Engines and Generators

Auxiliary engines are smaller engines used to generate electricity for onboard operations, including lighting, navigation equipment, HVAC systems, refrigeration, and communication systems. These engines often run for long hours and must be supported by efficient cooling and lubrication systems to prevent overheating and wear.

3. Pumps and Piping Systems

Pumps play a crucial role in various applications onboard, such as ballast control, bilge operations, fuel transfer, freshwater circulation, and firefighting systems. These pumps are connected through extensive piping networks that must be corrosion-resistant and reliable to prevent failures that could endanger the vessel or environment.

4. Boilers and Heat Exchangers

Marine boilers produce steam for various functions, including fuel heating, cargo tank heating, and auxiliary power generation. Heat exchangers are used in engine cooling systems to transfer heat from engine fluids to seawater or fresh water. These components often face high pressure and temperature variations, making material selection vital for safety and efficiency.

Challenges in Marine Environments

Ships operate in one of the most corrosive environments known—saltwater. Saltwater not only accelerates corrosion in metals but also introduces microbial activity, temperature fluctuations, and chemical exposure, particularly in fuel and wastewater systems. These challenges can degrade machinery performance, increase maintenance needs, and shorten component lifespans if not properly addressed.

Why Stainless Steel 904L is Preferred

Stainless steel 904L is an austenitic alloy known for its high resistance to pitting, stress corrosion cracking, and general corrosion. Originally developed for the chemical industry, it has found widespread use in marine applications due to its excellent performance in chloride-rich environments.

This alloy is ideal for piping, tubing, and structural components exposed to seawater, oil, and other corrosive agents. Its high nickel and molybdenum content makes it especially durable, even when used in highly acidic or saline conditions.

When sourcing materials for ship systems, working with a ss 904l tube manufacturer ensures that the components used meet strict quality control standards and are suitable for high-pressure, high-temperature marine applications.

Choosing the Right SS 904L Pipe Supplier

Equally important is the reliability of the supplier. A trustworthy ss 904l pipe supplier provides not only consistent quality but also traceability, compliance with marine certifications, and prompt delivery—critical for shipyards and maintenance schedules. Whether for new builds or retrofits, sourcing high-grade 904L stainless steel from a credible supplier minimizes downtime, reduces maintenance costs, and enhances the overall safety of the vessel.

Conclusion

Ship machineries are complex systems that require robust design, expert engineering, and, importantly, the right materials to function safely and efficiently. Stainless steel 904L stands out as a high-performance material for marine environments, especially in applications involving corrosive exposure and mechanical stress.

As the maritime industry continues to adopt more sustainable and efficient technologies, the demand for durable materials like 904L stainless steel will grow. Collaborating with a certified ss 904l tube manufacturer and a reliable ss 904l pipe supplier ensures that marine systems are built to endure, maximizing performance and minimizing risk on the high seas.