Introduction

The hard coating market is gaining momentum globally due to the rising need for surface protection in high-performance applications across automotive, industrial, medical, and optical sectors. Hard coatings provide resistance to abrasion, corrosion, and wear, significantly extending the life of components and tools. These coatings are typically applied using advanced deposition techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD), offering exceptional mechanical and thermal properties.

Market Overview

In 2024, the global hard coating market was valued at around USD 1.4 billion and is projected to reach USD 2.6 billion by 2033, growing at a CAGR of 6.9%. The demand is driven by increased applications in cutting tools, automotive parts, aerospace components, and protective eyewear, among others. Advancements in coating materials and processes are also playing a key role in expanding the scope of hard coatings.

Key Market Drivers

- Increasing demand for durable tools and components in manufacturing and machining 2. Growth in automotive production and the use of coated parts for enhanced performance 3. Rising adoption of scratch-resistant coatings in consumer electronics and optics 4. Technological advancements in deposition methods for higher coating quality and efficiency 5. Expansion of healthcare devices requiring biocompatible and wear-resistant coatings

Market Segmentation

By Material Type

- Nitrides (TiN, CrN, AlTiN)

- Oxides (Al₂O₃, ZrO₂)

- Diamond-Like Carbon (DLC)

- Carbides (TiC, WC)

- Others (Silicon Nitride, Borides)

By Deposition Technique

- Physical Vapor Deposition (PVD)

- Chemical Vapor Deposition (CVD)

- Sputtering

- Ion Plating

By Application

- Cutting Tools

- Decorative Coatings

- Automotive Components

- Medical Devices

- Optical Lenses

- Industrial Machinery

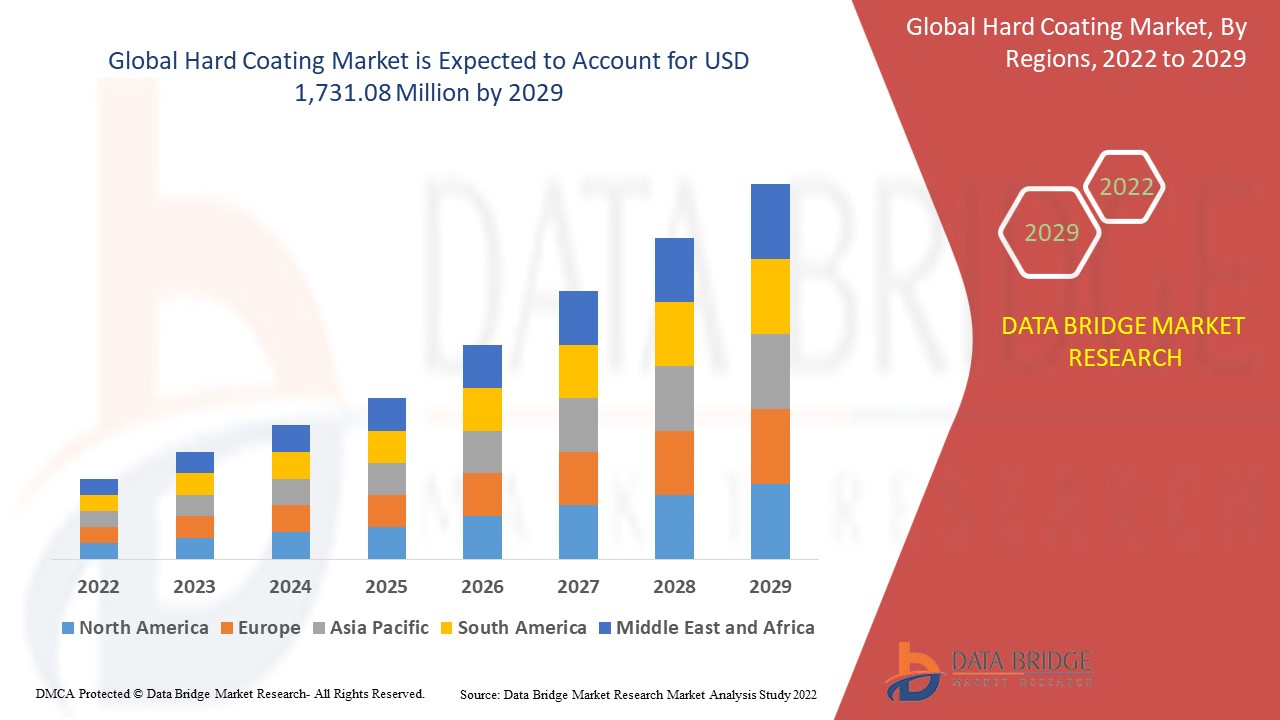

Regional Insights

North America leads the global hard coating market due to its strong manufacturing base, demand for high-performance tooling, and R&D in coating technologies. Europe follows closely, especially in automotive and aerospace industries where high-end surface treatment is crucial. The Asia-Pacific region is experiencing the fastest growth, driven by industrial expansion, electronic manufacturing, and government-led infrastructure development in countries such as China, India, South Korea, and Japan. Latin America and the Middle East & Africa are emerging markets with growing demand from mining, energy, and machinery sectors.

Emerging Trends

- Development of nanostructured coatings for enhanced hardness and thermal stability 2. Growing use of eco-friendly and water-based coating technologies 3. Hybrid coating systems combining multiple material types for multifunctional surfaces 4. Increased automation and AI integration in coating application processes 5. Customization of coatings based on specific industry needs and substrate compatibility

Challenges

- High capital investment required for advanced deposition equipment and clean-room environments 2. Limited performance of some hard coatings under extreme chemical exposure 3. Technical complexity in achieving uniform coating thickness and adhesion 4. Environmental regulations surrounding the use of certain chemical precursors 5. Cost sensitivity in price-competitive markets such as consumer electronics and automotive

Competitive Landscape

Leading companies in the global hard coating market include OC Oerlikon, IHI Ionbond AG, Sulzer Ltd, CemeCon AG, Momentive Performance Materials, Morgan Advanced Materials, A&A Coatings, ASB Industries Inc., and Carl Zeiss Surface Technologies. These players focus on expanding their product portfolio, investing in R&D, and partnering with end-users to deliver application-specific coating solutions. Strategic collaborations with tool manufacturers, healthcare providers, and automotive OEMs are helping to strengthen market presence.

Future Outlook (2024–2033)

- Continued innovation in coating materials such as nanocomposites and ultra-hard ceramics 2. Broader adoption of hard coatings in renewable energy sectors like wind and solar components 3. Increased use of coatings in 3D printed and additive manufactured parts 4. Standardization of quality benchmarks and certification across industries 5. Integration of digital technologies for real-time monitoring and control of coating processes

Source: https://www.databridgemarketresearch.com/reports/global-hard-coatings-market

Conclusion

The hard coating market is poised for consistent growth as industries across the globe demand improved durability, thermal stability, and corrosion resistance. With advancements in materials science and deposition technologies, hard coatings are becoming more versatile, efficient, and environmentally friendly. Companies that prioritize innovation, cost-effectiveness, and industry-specific customization will be well-positioned to capture growth opportunities in this expanding global market.