Pacemakers are among the most vital medical devices developed in modern cardiology. These compact implants help regulate abnormal heart rhythms, ensuring the heart functions efficiently and steadily. At the core of a pacemaker’s durability and biocompatibility lies a remarkable material—titanium strip. Its unique characteristics make it ideal for use in life-saving implants, especially in demanding environments inside the human body.

In this blog, we explore how titanium strips are applied in pacemaker components, their key benefits, and why choosing the right titanium strip supplier is crucial to the reliability of such sensitive medical devices.

Why Titanium Is a Go-To Material in Medical Devices

Titanium has long been trusted by the medical community due to its rare combination of properties:

- Biocompatibility: It does not react with human tissue or bodily fluids.

- Corrosion Resistance: Resists degradation inside the body, even after decades.

- Lightweight yet Strong: Offers high strength-to-weight ratio, essential for implants.

- Non-Magnetic: Safe for MRI environments.

When processed into thin, flexible strips, titanium becomes ideal for use in compact devices such as pacemakers. This is where the role of a dependable titanium strip supplier becomes vital, as quality and consistency can directly affect device performance.

What Is a Titanium Strip?

A titanium strip is a thin, flat section of titanium metal, precisely engineered to tight tolerances and often used in electronic and medical applications. It can be fabricated from various grades of titanium, with Grade 1 and Grade 2 being commonly used for their purity and softness, and Grade 5 (Ti-6Al-4V) for higher strength applications.

In pacemakers, titanium strips serve multiple purposes:

- Housing and enclosures

- Electrical shielding

- Battery compartments

- Internal connectors and terminals

Applications of Titanium Strip in Pacemakers

Let’s take a closer look at the core uses of titanium strips in pacemaker design and function.

1. Casing and Enclosure

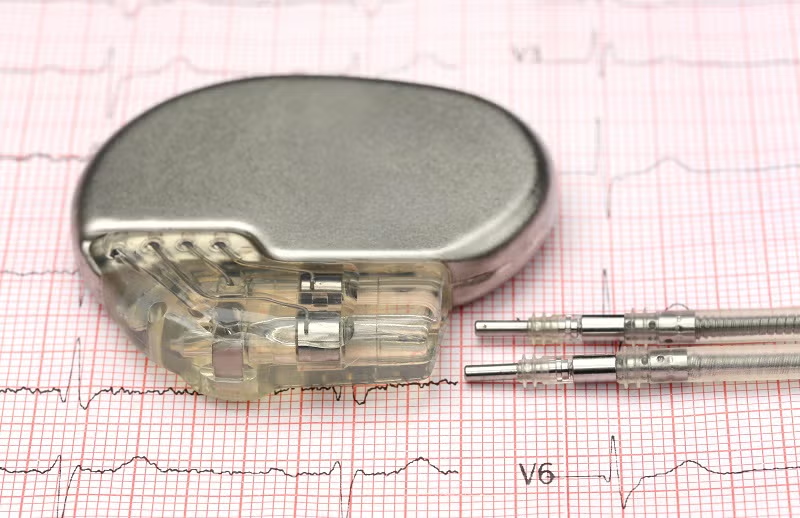

Perhaps the most critical role of titanium strip in pacemakers is in the outer casing. The casing must be strong, lightweight, and completely non-reactive with bodily fluids. Titanium strips are formed and welded into a sealed shell that protects the internal electronics and battery from the body’s internal environment.

The superior corrosion resistance of titanium ensures that the pacemaker can remain inside the body for 10–15 years or more without failure.

2. Internal Electrical Components

Titanium strips are also used internally as connectors, shields, or frames to mount electrical components. Their excellent conductivity and mechanical strength make them ideal for supporting microelectronics while maintaining signal integrity.

These applications demand extremely high material purity, another reason why medical device manufacturers rely on a trustworthy titanium strip supplier who can meet strict medical-grade standards.

3. Battery Housing and Insulation

The battery is a vital part of the pacemaker, and titanium strips are often used to form the compartments that hold and protect battery cells. The material’s resistance to corrosion and leakage ensures safety, while its low permeability to gases prevents moisture or oxygen from entering the device.

4. Electromagnetic Shielding

Titanium strips also act as shields to block electromagnetic interference (EMI), which could otherwise disrupt pacemaker function. This shielding is particularly important for patients exposed to external fields in daily life—like those generated by household electronics or medical equipment.

Benefits of Using Titanium Strip in Pacemakers

✔ Biocompatibility

Titanium is one of the few metals accepted by the human body, making it ideal for long-term implants like pacemakers.

✔ Lightweight and Durable

A small and unobtrusive implant is crucial for patient comfort. Titanium strips offer strength without adding weight or bulk.

✔ Corrosion and Chemical Resistance

Titanium’s ability to resist corrosion by bodily fluids extends the life of the device, reducing the need for replacement surgeries.

✔ Fabrication Flexibility

Titanium strips can be cut, stamped, bent, and welded into complex forms—essential for precision electronics in pacemakers.

How to Choose the Right Titanium Strip Supplier

When medical applications are involved, not all materials or suppliers can be trusted. Choosing a reliable titanium strip supplier ensures:

- Consistent quality and composition

- Certification to medical-grade standards (e.g., ASTM F67, ASTM F136)

- Precision in thickness, width, and surface finish

- Cleanroom-level packaging and delivery

A reputable supplier will also provide traceability documentation, batch reports, and compliance with global standards like ISO 13485.

Industries Beyond Pacemakers Using Titanium Strip

While pacemakers are a prominent example, the use of titanium strips extends to other medical applications as well:

- Implantable defibrillators

- Cochlear implants

- Dental implants

- Surgical instruments

- Orthopedic hardware

In each of these applications, the titanium strip plays a structural or functional role, and the quality of the supplier determines the device’s safety and success.

The Future of Titanium Strip in Medical Technology

As technology advances, pacemakers are becoming even smaller and more powerful. Titanium strip will continue to be a core material in enabling miniaturization while maintaining strength, performance, and biocompatibility.

Emerging technologies like leadless pacemakers and wireless telemetry further increase the demand for high-precision materials supplied by specialized titanium strip suppliers.

Final Thoughts

Titanium strip plays an indispensable role in the design and function of pacemakers. Its unique combination of strength, biocompatibility, and corrosion resistance makes it the material of choice for safe, long-term implantation.

However, the success of a pacemaker doesn’t only depend on design—it starts with choosing the right titanium strip supplier. Manufacturers must partner with suppliers who meet stringent medical standards, offer consistent quality, and deliver precision-engineered strips fit for life-saving applications.

As medical devices continue to evolve, titanium strip will remain a foundational component—quietly powering the heartbeat of patients worldwide.