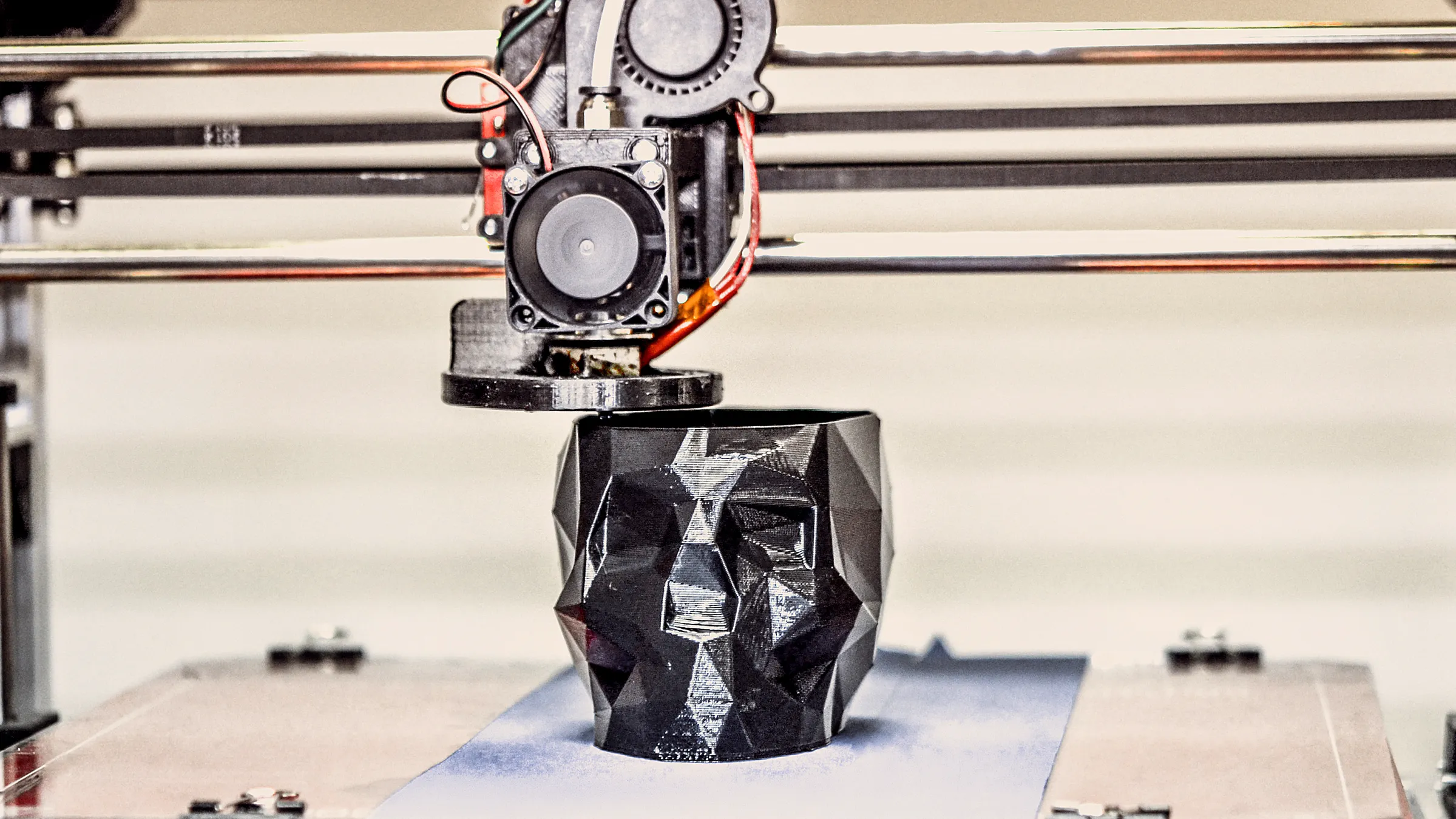

3D printing has been called the next big manufacturing revolution. After all, this technology can create objects of any shape or size in minutes instead of hours or days. Of course, 3D printing is not new by any means. It has been around for more than 30 years. However, its popularity has surged due to computer technology and materials science advances. This article will explore some of the benefits of 3D printing and how it can improve manufacturing processes. By understanding this technology, you can ensure that your company remains competitive in today’s economy.

What is 3D Printing?

3D printing is a process by which objects are created from a digital model. This technology was developed in the 1980s, but its popularity has exploded recently due to its ability to create customized products. 3D printing is not just limited to products; it also has applications in manufacturing and design.

One of the most significant benefits of 3D printing is that it allows for the customization of products. You can create products exactly how you want them without going through a traditional manufacturing process. This saves time and money and allows manufacturers to customize their products for specific needs.

Another significant benefit of 3D printing is that it’s environmentally friendly. Manufacturing processes typically use a lot of energy, which can be damaging to the environment. With 3D printing, however, manufacturing can take place without any harmful emissions.

There are a few different types of 3D printers available today. The most common type is stereolithography (SLA), which uses lasers to print objects from digital models. SLA printers are expensive, but they’re capable of very high-quality prints.

How is 3D Printing Used in Manufacturing?

3D printing is a manufacturing process that uses additive manufacturing to create a three-dimensional object from digital instructions. This technology has been around for years, but its use in the manufacturing industry has recently taken off due to its potential to reduce the time and cost of creating products.

There are several ways that 3D printing can be used in manufacturing. One application is for creating prototypes or testing parts. With this method, manufacturers can quickly create a small number of parts to test or evaluate before investing in larger production quantities.

Another use for 3D printing is in the production of final products. With this approach, manufacturers can create one or more copies of an item exactly how they want it without producing a whole batch of items and then have them customized. Additionally, 3D printing in production allows factories to lower inventories by producing only what is needed at any given time rather than stockpiling inventory.

While there are many benefits to using 3D printing in manufacturing, some challenges must be addressed. For example, most printers use liquid plastic as the construction material, which requires careful handling and temperature control so that it does not melt during printing. Additionally, because 3D printers build objects layer by layer, defects can sometimes occur when objects are printed out of thin plastic layers. However, with advances in technology, these issues should soon become easier to overcome.

The Advantages of using 3D Printing in Manufacturing

3D printing technology is revolutionizing manufacturing by allowing for the creation of multiple copies of a product or part with minimal waste. This is particularly useful when multiple iterations are needed to create a final product.

In addition to being less wasteful, 3D printing can be more accurate than traditional manufacturing methods. This is because 3D printers use digital models printed layer by layer, creating products with a high degree of precision. Because of this, 3D printing can be used to create parts for products such as medical devices and aircraft.

Finally, 3D printing offers an opportunity to overcome challenges that traditional manufacturing methods have difficulty dealing with. For example, 3D printing can produce complex items that are difficult or impossible to manufacture using other methods.

What are the Disadvantages of using 3D Printing in Manufacturing?

3D printing can be a great tool for manufacturing, but it has some disadvantages. For one, 3D printing is expensive. It can also be time-consuming and difficult to scale up production. Additionally, 3D printing technology is not always compatible with traditional manufacturing processes.

Conclusion

3D printing is quickly becoming a mainstay in the manufacturing industry, and for good reason. With its ability to create customized parts quickly and cheaply, 3D printing is changing the way products are designed and manufactured. Whether you want to create prototypes or production-ready parts, 3D printing is an essential technology that should be part of your toolkit. So what are you waiting for? Get started today!