Cable drag chains have many functions today. Also known as cable carriers or cable chains, these flexible hollow structures guide, support, and protect hydraulic lines, hoses, and cables when they are moving. The drag chains ensure the lines, cables, and hoses don’t become tangled or sustain damage when a machine is in motion. If this happens, there may be an accident or the machine may malfunction and lead to downtime.

Cable Drag Chain Materials

Manufacturers produce steel and plastic cable drag chains. The material used depends on the application as well as its restrictions and requirements. Each material comes with its own advantages manufacturers must consider when constructing these chains.

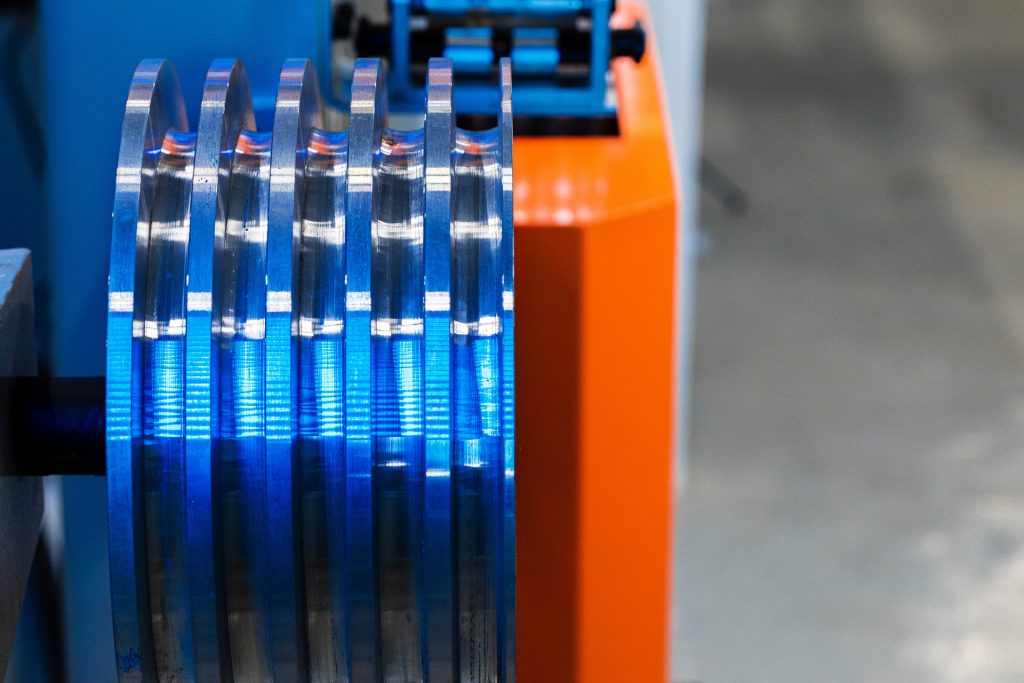

Steel Cable Drag Chains

Steel drag chains work best in situations where the line, hose, or cable will be exposed to high temperatures or heavy-duty loads. The use of these chains allows maximum unsupported spans. Coolant, abrasives, and hot chips cannot reach the hoses, lines, and cables when this material is used. In addition, the use of steel allows manufacturers to operate machinery at higher speeds and when rapid accelerations are expected.

Manufacturers use a variety of metals when creating these cable carriers. They choose stainless steel when the application calls for increased environmental resistance combined with a heavy load carrying capacity. Heavy loads call for zinc-plated steel, while a hybrid metal may be used when design flexibility is needed but the manufacturer cannot sacrifice higher acceleration and speeds.

Plastic Cable Drag Chains

In the early 1970s, manufacturers turned to plastic when making cable drag chains. Today, plastic versions are as popular as their steel counterparts. In fact, plastic versions work best for certain applications. The manufacturers use high-strength nylon filled with glass or special polymers when making these cable carriers.

They do so because these materials resist corrosion, hold up with time, and can be used for high-speed and acceleration applications along with operations that require long travel times. Companies appreciate the glass-filled nylon carriers because they can be operated in temperatures from -40 degrees Fahrenheit to 250 degrees Fahrenheit.

The specialized plastics allow for the creation of cable drag chains that protect the cable, line, or hose from flying metal chips and chains for use in clean rooms. Manufacturers also use plastic cable carriers for applications involving the manufacturing of sensitive electronic devices and those that require the use of combustible materials.

Cable Carrier Applications

Cable carriers appear in a variety of locations. Port cranes rely on these devices, as do green energy systems. A person working with machine tools often relies on these cable carriers, and they appear in vehicle transporters and washing systems. Furthermore, process and automation equipment benefits from the use of cable drag chains.

Speak with a cable drag chain manufacturer to learn whether plastic or metal should be used in the creation of these carriers. The manufacturer is a great resource when making this decision. They can make recommendations on which product to buy and why, allowing the customer to have confidence in the choice they make. Learn more today about these devices, their uses, and their benefits.